Supply Chain Issues For Canadian Retailers Expected Into 2025: Expert

Supply Chain Issues For Canadian Retailers Expected Into 2025: Expert

Interestingly 2022 was a period of adjustment across the supply chain, and it still continues to evolve as we enter 2023, says expert Gary Newbury.

“In 2020 retailers were faced with the prospect of the arrival of a glut of stock into, sometimes, dormant estate arising from lockdowns, which required swift action to cancel merchandise orders. Retailers also needed their website/online services to scale quickly as consumers changed not only their category spending, but also their channel. Most retailers found themselves in a mad scramble, focusing on triaging demand and supply and grabbing whatever inbound trucking and outbound delivery capacity they could find,” said Newbury, Founder of RetailAID Inc. and an Award Winning Strategic Advisor and Delivery Executive across the end to end consumer driven supply chain.

“Further disruption occurred in 2021 with continued (Zero) COVID lockdowns, the Ever Given blockage, significant West Coast port congestion due to a nearly 25 per cent lift in cube leading to rollovers at the origin port (ships leaving without your orders on them!). Complexities surfaced through a lack of supply chain visibility. There were stock outs at factories showing retailers were not as aware of interdependencies in complex supply networks supporting factories 6000 miles away. There were also some extreme weather events, and growing and significant staff shortages in “essential” roles.

“Many modes of transport suffered asynchronous discontinuity, basically things fell apart quickly and getting stock was often reduced to a very stressful firefight with shipping lines, trucking companies, ports and factories, with very little surety as to the exact disposition/status of orders placed. The upshot of this is retailers didn’t need to run intense promotional campaigns during 2021. Demand was unusually high and inventory short. If you had sufficient inventory you could win new customers, if you didn’t, you lost loyal ones.”

He said this supply chain tangle set in motion inflationary pressures, fanned by high government spending in policy areas such as furlough and direct subsidies. Inflation is bad for cost planning. Container charges rose 10-fold over a handfull of months and this smashed budgets and posed a real challenge to on shelf pricing.

Much of this cost was “absorbed” in the short term by retailers, unless they had a strong enough position to pass the costs on to consumers.

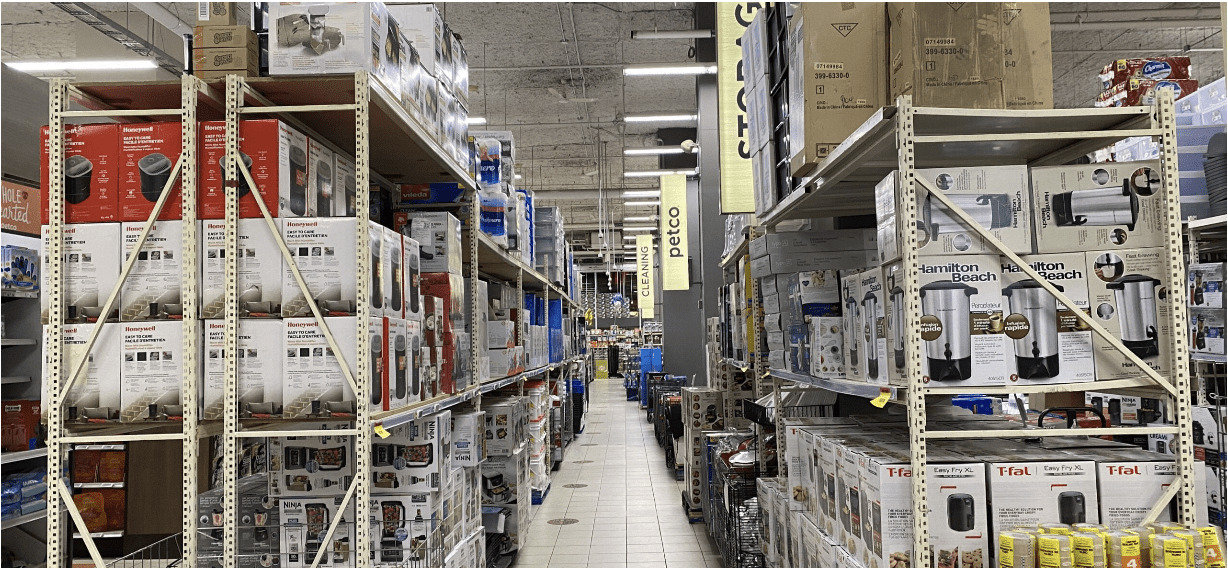

“Open 2022 and the balance swung quickly to an inventory glut for many retailers. Both Walmart US and Target declared their hand in Q1 and went to work on clearing their excess stock. This situation was not isolated just to these two apex retailers, it did, nonetheless, show a fundamental breakdown in the internal guide rails between marketing insights, demand planning and supply chain execution, and importantly, the shortfalls in genuine collaboration internally,” explained Newbury.

“The restrictions posed a clear challenge to the organizational culture of most retailers. Culture morphed often forming divisions within an organization. Each silo learnt how to adapt quickly and mobilize staff to what the leader perceived as important. More often than not, for most retailers, it was all hands to the pumps and little time was spent on resetting cultural norms. These were developed, by default, in real time. Suddenly, the supply chain, having sat in the background for decades, was the most important area of a retailer’s business.

“As consumers flocked back to stores, retailers found, once again, they were in a mad scramble to rebalance demand and their, often disjointed inventory position. War broke out late February and the world discovered complex supply chains originating or going via Ukraine. Energy reliance within the EU on Russia became abundantly clear, spiking further inflationary pressures. Some doubt has existed whether Canada is in a recession. The rapid upward trajectory of interest rates during 2022, suggested the Bank of Canada thought we were and started market interventions to calm inflationary pressures, I would argue a year too late.”

Newbury said the years 2023 and 2024 need to be looked at together as he believes we still have another two years of supply chain adjustment and transformation ahead until the final stage of rebalancing during 2025 arrives.

According to Newbury, the key challenges over this period are:

- This period, due to a reduction in overall discretionary spending, retailers need to find ways of differentiating themselves from their adjacencies. It is clear, now we have been working through the “Great Inventory Glut”, there is very little that can only be bought from one brand (Private label excepted). Experience and convenience are key in this equation and the efficacy of online services will need to be overhauled, technology inserted, repricing for online assortments and a much lower cost profile will be required to ensure e-commerce is profitable;

- Throughout the end-to-end supply chain, the pandemic highlighted significant visibility gaps, both physically as well as in forecasting demand and planning capacity. A thoughtful approach to deploying mature technology is key in better controlling the progress of merchandising orders through the system, and for creating forecasts that help with optimizing throughput. The leap to AI has not always been one that shows step change in performance, often it can show how badly organized and porous a business’s data gathering and data management is;

- One of the vital factors in successful supply chain and logistics operations is the ability not only to attract staff to key roles and activities, but to retain talented operatives. Considerable focus must continue to be on the employee experience and discovering the points of friction. At one level this could be pay levels, but more often than not, it can be how engaged the operatives feel they are in their workloads. This is often a factor of the opportunity to collaborate and really see a connection between “that last task done” and the overall goals of the retailer. Communicating strategy and key values of how people will be treated, and expectations clearly, plus demonstrating these in action will go a long way towards improving engagement, achieving superior performance and making the retailer’s supply chain as a destination employment space.

Newbury said the “Just in Time” retail supply chains are a classic example of misthinking how to efficiently respond to consumer demand by constructing merchandising processes and supply chains that are planned out one, two or even three seasons and committing to these plans. These are designed on a “push”, rather than a demand-pull approach and have inherent inefficiencies which we can see in markdowns, clearance and landfill, he said, adding there’s a couple of blindingly obvious factors in the demise of our supply chain designs that manifested over the last three years.

The first is the lack of concerted risk management strategies and/or ensuring that risk stood pari passu (side by side) with the focus on individual logistical element cost optimization.

“Frankly, the way retailers manage their budgets has led us down a path for the cheapest sources, often independent of the risks involved with the origin and transportation distances – what could go wrong here? A question that clearly had not been asked with sufficient robustness during the previous decade,” he said.

Newbury added that there’s also been a lack of real collaboration. The way the current paradigm works to working with partners is “I win if you lose”. This has guided so much of the interface between the retailer and its suppliers. There remains limited motivation to pool energy to bring product to market quickly and respond, very efficiently, to consumer behavioural change. As retail expert George Minakakis stated in The Great Transition, “Competitors are not the enemy, the inability to drive trends is,” said Newbury. The key to driving trends is the ability to coordinate and collaborate internally (marketing insights, demand planning and supply chain execution), as a basis for being able to understand how to collaborate with third parties to drive sustainable levels of profitability, he said.

“Retailers need to be building a clear strategy against a pictorial representation of what 2025/26 will be. Along this pathway will be the introduction of technological enablers. My thoughts, only mature technologies should be introduced. However prior to that, the strategy should provide a structure of how the triad of People, Process and Technology is to be addressed. Too often the “go to” is to fix long-standing internal business challenges with technology, rather than review culture, leadership, organizational structure, goal setting and incentives,” he said.

“I am optimistic our retailers will be looking to do good things around technologies including micro/nano fulfillment centres, AI to help with forecasting, optimization and improving customer experience, however, unless these core problems are addressed urgently, the adoption of more technology will be disappointing.

“For those outside the supply chain, the focus may have switched back to improving and optimizing more traditional areas, such as Stores and Merchandising. Unfortunately, the supply chain remains a major challenge when volumes start to pick up. This will accelerate the surfacing of many of the problems and unresolved issues that abated as volumes trended down due to China’s Zero COVID lockdowns during the latter stages of 2022.

“The time now is to take some bold moves in redesigning retail supply chains for real agility, based on optionality, collaboration and the thought that the supply chain is a competitive tool in modern retailing, supporting stores and delivering e-commerce experiences on consumers’ porches across Canada.”

Source Retail Insider. Click here to read a full story